| Hardware: The stepper motors are 6 wire unipolar steppers that are controlled by a TI SN754410NE H-Bridge that is connected to a PIC 16fF84 microcontroller. The PIC sends pulses to the H-Bridge that move the motor in 1 degree/step increments in either a clockwise or counter clockwise direction. An infrared detector is used to sense IR pulses sent by the TV remote control A DPDT relay is used to provide two NO SPST contacts that can be used to activate sounds or other accessories.

|

| Schematic: Click on this thumbnail to see the schematic |

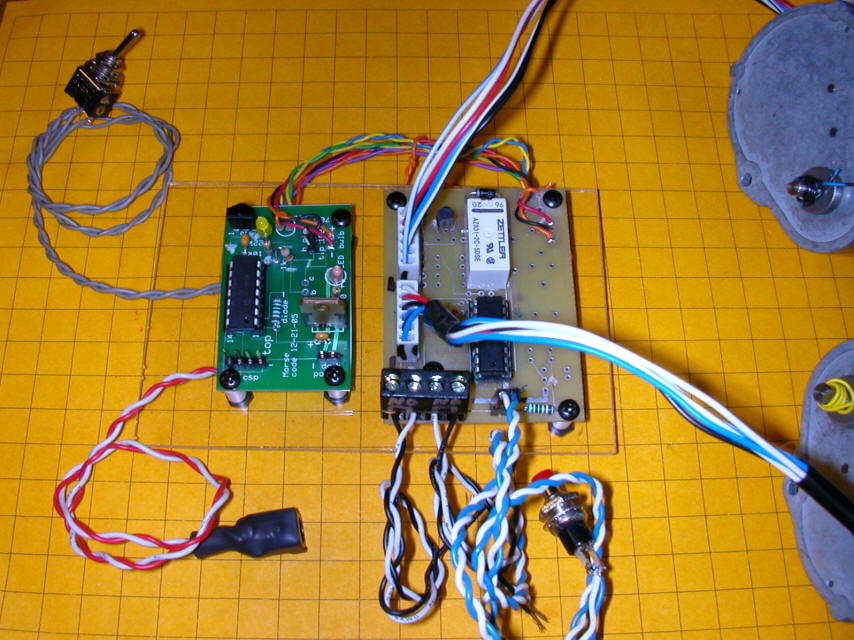

| Completed unit: Here the microcontroller board is shown (top left / green board) along with the auxiliary board (bottom left / brown board) and the two geared Hurst stepper motors.

In this view of the microcontroller board the programming jumper is in the upper right area. Power is applied in the lower right. The IR sensor is in the upper left next to the yellow LED.

The stepper motors connect to the two six pin headers on the left side of the second board, seen below. The activation switch (which moves the bridge up or down) connects at the bottom center and the sound unit or other accessory connect via the screw terminals on the bottom left.

|

|

Configuration: Configuration is done be by way of an infrared TV

remote control unit.

|

| Programming: To test the unit follow this procedure: 1. Make sure the programming jumper is on the two jumper

pins on the green microcontroller board. This allows the

remote control unit to operate the motors |

| Changing the programmed step number: 1. To change

the number of steps moved by CHAN+ and CHAN- press the END key

(lower left) |

| Fine adjustments: To move the motor in small increments you can press the following buttons (with the programming jumper installed)

|

| Automatic operation: Once the proper number of steps has been determined and programmed remove the programming jumper. You can store it by putting in on one of the two pins. Pressing the UP/DOWN button will move the motors the programmed number of degrees. The first press of UP/DOWN moves the motors CW. The second press moves the CCW. Note. If power is lost while the bridge is up the unit will remember that is was up and the next press will put the bridge down. If power is lost in the middle of an up or down operation the bridge controller will not know where the bridge was stopped and the unit must be reset by with the remote control unit - (install the programming jumper and use the 1-6 keys (as above) to move the bridge to the bottom or top position before restarting.

|

| As Shipped: Connect the unit as below for testing. The grey wires on the left go to the Program / Operate toggle switch. In the program position the remote control can change setting and align the motors. In the Operate setting the push button (at the end of the blue/white wires) activates the motors either up or down. Note that the blue / white wires terminate in a small plug that goes into the board next to the black screw terminal connector. The red/white wires in the lower left terminate in a power connector that goes to the power supply. The two pairs of black / white wires are for the NO contacts on the relay. They connect via the two sets of screw terminals marked NO. Additional items shipped include

The motors connect as in the photo below. There is a black mark on one end of each connector that goes next to the black mark on the board.

|

| Software - revision 12-3-06 - most features working: |

| '12-3-2006 version 1-2 'works properly with Mike Gruber's motors - 'push ENTER to go to program mode - type 4 digit number in degrees 'vol up / vol dn does CW & CCW tests ' loop var byte temp0 var byte temp var word temp1 var word temp2 var word temp3 var byte LEDTemp1 var byte LEDTemp2 var byte LEDTemp3 var byte TempByte var byte digit var byte PauseWord var word TempWord var word TempWord2 var word value var byte LED var porta.4 'also high 10 ProgramButton var porta.2 'low when hit relay var portc.5 StartSwitch var porta.5 'pin 2 CW var bit 'CW if 1, CCW if 0 CW_CCW var bit 'stores what was done last zero con 136 one con 128 two con 129 three con 130 four con 131 five con 132 six con 133 seven con 134 eight con 135 nine con 136 channelUP con 144 channelDOWN con 145 volumeUP con 146 volumeDOWN con 147 OK con 148 Menu con 224 ENTER con 139 x VAR BYTE steps VAR WORD stepArray VAR BYTE(4) stepArray[0] = %00001010 stepArray[1] = %00000110 stepArray[2] = %00000101 stepArray[3] = %00001001 'clear TRISc = %11100000 IRpulse_length var word(13) xx var Byte Command Var Byte IRin var portc.4 'pin 6 ansel = 0 cmcon0 = 7 trisa.4=0 'make leds output trisa.5=1 trisc.5=0 trisa.2=1 'start button input trisc.4=1 'IR input data @0, 2,208, 0 ' 1,104 = 360 degrees - 3rd digit CW or CCW on start read 0,temp read 1, temp1 read 2, CW_CCW pauseword = temp*256 pauseword=pauseword + temp1 goto Verytop: again: high relay:pause 1000:low relay:pause 1000 if programbutton=0 then for temp=1 to 5 high led:pause 200:low led:pause 200 next temp endif if startswitch = 0 then for temp=1 to 5 high led:pause 100:low led:pause 100 next temp endif if programbutton=1 and startswitch=1 then toggle relay pause 500 endif goto again: VeryTop: low portc.0:low portc.1:low portc.2:low portc.3 start: low relay command=0 gosub GetIR if Programbutton=0 then goto Operate: endif if command = OK then VeryTop: if command = ChannelUP then SpinCW: if command = ChannelDown then SpinCCW: if command = VolumeUp then Test1: if command = VolumeDown then test2: if command = Enter then GetRevSettings: if command = one then CWone: if command = two then CWfive: if command = three then CWten: if command = four then CCWone: if command = five then CCWfive: if command = six then CCWten: goto start: CWone: CW=1 gosub step1 pause 100 goto verytop CWfive: CW=1 for temp3=1 to 5 gosub step1: next temp3 pause 100 goto verytop CWten: CW=1 for temp3=1 to 10 gosub step1: next temp3 pause 100 goto verytop CCWone: CW=0 gosub step1 pause 100 goto verytop CCWfive: CW=0 for temp3=1 to 5 gosub step1: next temp3 pause 100 goto verytop CCWten: CW=0 for temp3=1 to 10 gosub step1: next temp3 pause 100 goto verytop SpinCW: cw=1 for tempword=1 to pauseword gosub step1: next Tempword goto verytop: SpinCCW: cw=0 for tempword=1 to pauseword gosub step1: next Tempword goto verytop: Test1: cw=1 tempword2=360 for tempword=1 to tempword2 gosub step1: next tempword goto verytop: Test2: cw=2 tempword2=360 for tempword=1 to tempword2 toggle LED gosub step1: next tempword goto verytop Operate: if programbutton=1 then start: low relay if startswitch = 0 then Operate: if CW_CCW=1 then cw=1 else cw=0 endif cw_ccw = not(cw_ccw) write 2,CW_CCW high relay :high led ':pause 1000:low relay:low led:pause 1000:high relay:high led:pause 500 for tempword=1 to pauseword gosub step1 next tempword low relay :low led WaitForRelease: if startswitch=1 then WaitForRelease: goto verytop Test3: cw=1 tempword2=360 for tempword=1 to tempword2 gosub step1: next tempword low portc.0:low portc.1:low portc.2:low portc.3 pause 2000 cw=2 tempword2=360 for tempword=1 to tempword2 toggle LED gosub step1: next tempword low portc.0:low portc.1:low portc.2:low portc.3 goto verytop Test4: cw=1 tempword2=pauseword for tempword=1 to tempword2 gosub step1: next tempword pause 2000 cw=2 tempword2=pauseword for tempword=1 to tempword2 toggle LED gosub step1: next tempword return GetIR: Getstartbits: Pulsin IRin ,0,IRpulse_length(0) if IRpulse_length(0) < 200 then return Endif for xx=1 to 12 pulsin IRin,0,IRpulse_length(xx) next xx displaybits: if IRpulse_length(1) < 100 then Command.bit0 = 0 Else Command.bit0 = 1 endif if IRpulse_length(2) < 100 then Command.bit1 = 0 Else Command.bit1 = 1 endif if IRpulse_length(3) < 100 then Command.bit2 = 0 Else Command.bit2 = 1 endif if IRpulse_length(4) < 100 then Command.bit3 = 0 Else Command.bit3 = 1 endif if IRpulse_length(5) < 100 then Command.bit4 = 0 Else Command.bit4 = 1 endif if IRpulse_length(6) < 100 then Command.bit5 = 0 Else Command.bit5 = 1 endif if IRpulse_length(7) < 100 then Command.bit6 = 0 Else Command.bit6 = 1 endif if IRpulse_length(8) < 100 then Command.bit7 = 0 Else Command.bit7 = 1 Endif If Command.bit7 = 0 then 'Bit 7 is one of the device bits Command = Command + 1 Endif If Command = 10 then Command = 0 Endif return Step1: for temp0=1 to 4 if CW = 1 then steps = steps + 1 else steps = steps - 1 endif portc = stepArray[steps //4] high relay pause 3 '2 seems to be a minimum next temp0 return GetRevSettings: digit=4 PauseWord=0 high LED:pause 1000:low LED GetRevSettings0: gosub getir if command=0 then GetRevSettings0 if command > 137 or command < 128 and command <>139 and command <> 0 then goto VeryTop: 'abort on non number 0-9 endif if command=139 then GetRevSettings0 Value=command-127 if Value = 10 then value=0 if value=0 then high LED:pause 500:low LED for tempbyte=1 to value:High LED:pause 200:low LED:pause 200:next tempbyte PauseWord=PauseWord*10+Value digit=digit-1 pause 200:command=0 if digit=0 then temp0= pauseword / 256 write 0, temp0 temp1 = temp0*256 temp2= pauseword-temp1 write 1, temp2 'gosub test4: goto VeryTop: endif goto GetRevSettings0 |