-

The Auto-Reverse Controller (ARC) takes running trolleys and other

point-to-point rail cars to a higher level than has been available before.

The microprocessor controlled device automatically learns the length of your

track as it smoothly accelerates and decelerates the car at each end. -

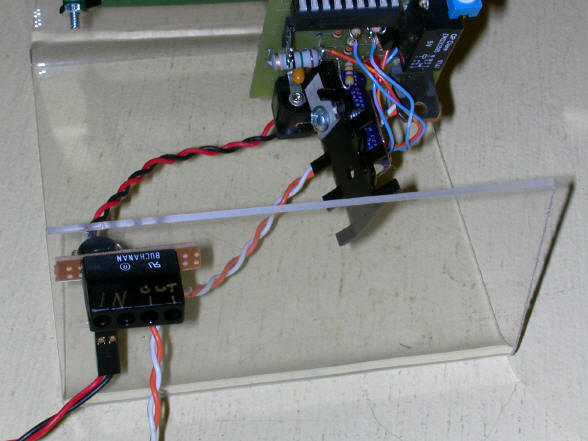

The only connections are to your power supply and to the track. No

additional sensors are needed, only the normal cut rail and diode that such

systems traditionally use must be installed at each end.

|

-

Features

-

A bright, clear backlit 4 line LCD display keeps

you posted on the train's four states of operation:

-

acceleration as the train smoothly

starts up

-

constant speed operation as the

train "cruises" between the ends of the track

-

deceleration as the train nears the

end of its run

-

delay as the train waits either a

set number of seconds or a random time before it reverses and continues on its

way

-

The "cruise" time is automatically

adjusted during the train's first few laps as the system learns the length of

the track

-

The ARC continues to monitor and

adjust its timing even if you change the power level as it is operating

-

You can easily change the delay to:

|

-

Track Preparation

-

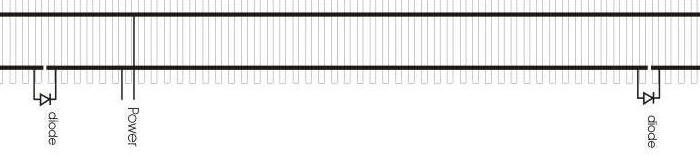

A section of track must be cut and

a diode must be installed across the cut at each end of the track

-

-

Both track sections need to be cut

on the same rail and both diodes must be installed with the same polarity, that

is the band on the diodes must point in the same direction.

-

-

Click here for more information on preparing

track

|

-

Power Connection

-

The ARC will operate from either AC

or DC voltage. If you wish to manually adjust the speed of your trolley or

engine you can connect the ARC to the variable output from your transformer.

Note that the lap count will be lost if you turn the power setting much below 6

or 7 volts as the ARC will shut down and reset.

-

The voltage regulator on the board

can get very hot if more than 18 volts is supplied.

-

Controls

-

There are only two controls on the

unit

-

The push button switch is used to

enter the programming mode when the unit is first turned on.

-

The toggle switch is used to set

values once programming mode is entered. It can also be used to change the

train's speed dynamically as it runs.

|

-

Screen

-

The 4 line LCD screen is

continuously updated so that you know the current state of operation

-

The small potentiometer just below

the LCD connection to the circuit board can be

adjusted to change the contrast on the screen

|

- Screen modes during operation

- Accelerate

- The train accelerates from its

low speed setting and it high speed setting

- The numbers are expressed as a

percent of the highest speed that can be reached

- The rate of acceleration can be

changed in the setup menu

- Note that this mode can pass by

very quickly if the rate of acceleration is high and the range

between low and high speed is small

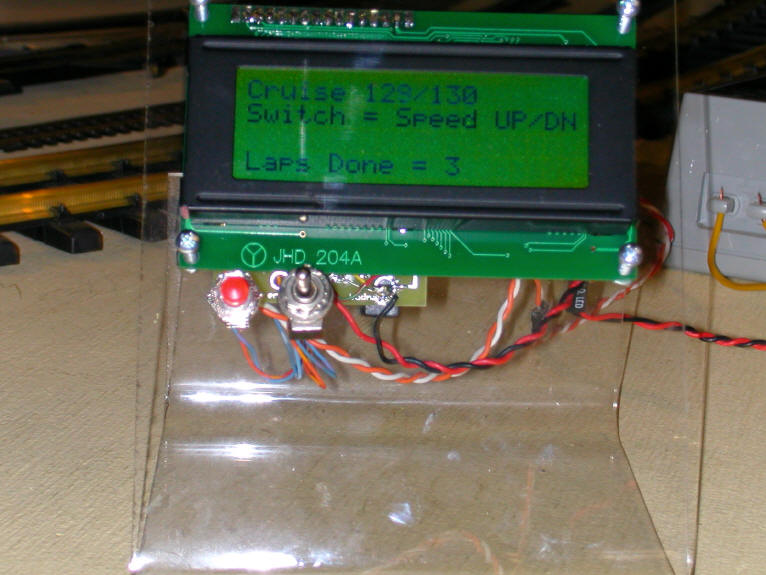

- Cruise

- During cruise the time that the

engine will be in this mode is displayed. The numbers

represent 1/10s of a second.

- While in this mode the train's

top speed can be increased or decreased with the toggle switch

- Decelerate

- This mode is identical to the

Acceleration mode but the train slows rather than speeds up

- During the first few laps the

train is likely to decelerate to its lowest speed before it

reaches the end of the track. If this happens the low speed

may be too low for the train to continue. Just push the

toggle switch UP to increase the low speed setting until the train

starts to operate again

- Pause

- The train pauses for either a set

or random number of seconds

- If you ever need to restart the

ARC you can press the program button while the unit is in pause

mode to return to the initial startup screen. Note that all

lap information will be lost but that the other settings will be

retained

- Lap counter

- The ARC keeps track of the number

of laps that have been run and displays them in all modes.

|

-

Getting started

-

Install cut / diode equipped track

at each end of the line of track

-

Connect the unit to the AC or DC output

of your transformer. This may be a constant or a variable power output, AC

or DC.

-

Connect the output of the unit to

the track

-

Place a trolley, small engine or

rail car on the track

-

Turn on the power

-

After the ARC initializes your

engine will begin its journey in one direction or the other

-

Once it hits an end it will delay,

reverse and continue

-

Note that the first 5 laps will

have a delay that is only 1/10 of the selected delay time - this facilitates

initial setup.

-

As the train completes laps you

will notice that the "cruise" time changes as it learns the length of the track

-

The display keeps track of the

number of laps that have been completed

-

Dynamic speed changes

-

High and low speed settings can be

changed by using the procedure in the next section but it may be easier to

change speeds while the train is running.

-

During "Cruise" you can use the

toggle switch to increase or decrease the top speed

-

During initial laps the train may

reach the end of the "Deceleration" mode before it hits the end of the track.

When this happens you can use the toggle switch to increase or decrease the

trains low speed setting

-

The ARC writes any speed changes to

memory so that they are retained for future runs.

|

-

Changing parameters

-

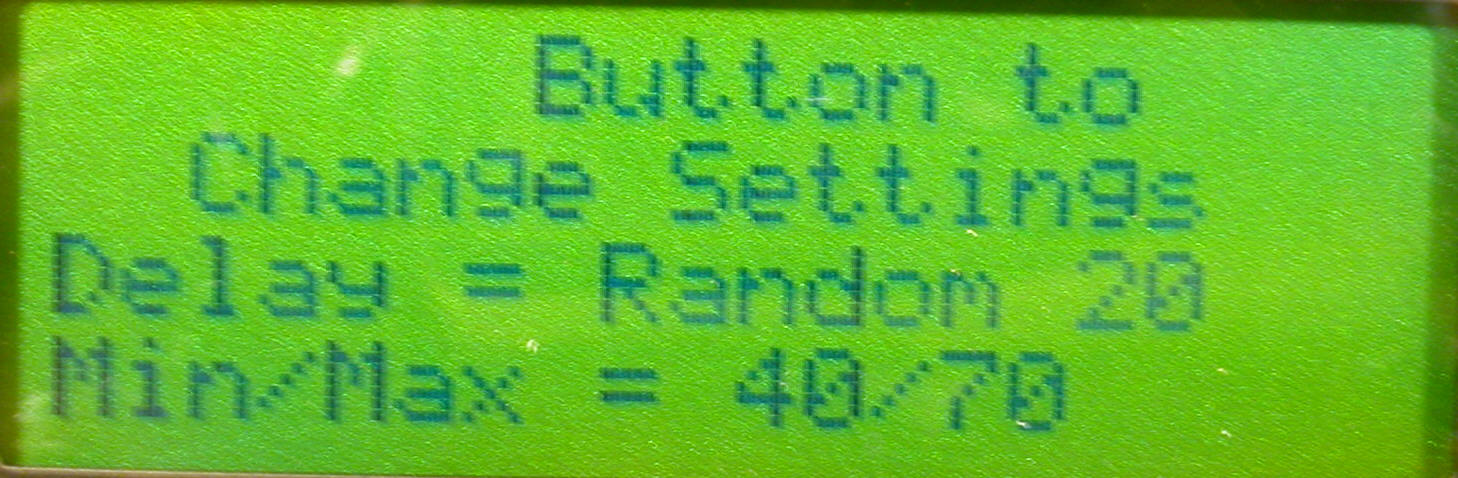

Delay Time

-

To change the delay time hold the

button until "DELAY =" is displayed

-

Move the toggle switch either up or down to enter the change

delay screen.

-

Push the toggle switch up to increase the delay and down to

decrease it

-

As the display indicates, the top of the delay range will give

random times and the bottom range fixed times.

-

When you have set the desired time press the button to write

that setting to memory and continue

-

You will be returned to the setup screens. Continue to

press the program button to move through the options.

-

Low Speed

-

To change the train's low speed

just continue holding the setup button, as above, until "LO SPEED =" is displayed

-

The low speed is normally set to a

value that allows the engine to just make it from one end of the track to

another.

-

Something between 30% and 60% works

well for most engines. The lower the voltage that you are supplying the

higher the percentage of that voltage you will need to supply so that it does

not stall at the end of its deceleration.

-

If it is set to low the train will

stall. If this happens see "Troubleshooting" for a quick fix.

-

The ARC will not permit the low

speed to be set to a value higher than the high speed

-

High Speed

-

To change the train's high speed

just continue holding the setup button, as above, until "Change Hi Speed" -

"Hold 4 More" is displayed

-

The high speed is normally set to

its maximum value, 255. That way the transformer can be used to adjust the

high speed.

-

If, however, you are using a

constant supply voltage you can decrease the value of the high speed to a value

less than 255. Under most circumstances this value should not be less than

150.

-

The ARC will not permit the high

speed to be set to a value lower than the low speed.

-

Acceleration rate

|

-

Troubleshooting

-

If the engine's low speed is set too

low it will slow during deceleration to a speed that will bring it to a complete

halt.

-

If this happens you will see

"Button to Speed Up" displayed on the screen

-

Hold the button until the engine

just starts moving

-

When you release the button the new

low speed setting will be automatically written to memory

-

You are likely to have to set the

low speed to a value above what will normally work with an engine or trolley.

This is because you have to overcome the inertia of a stopped engine. Try

resetting the low value to a number somewhere between where it stalled and where

it restarted.

-

If your track is dirty or poorly

connected the circuitry can detect a break in power from the track as being a

track end.

-

If your track has a significant

include or grade to it the system will have difficulty determining the length of

the track as it assumes that the time to run in both directions is the same.

The Auto Reverse Unit will still work but it is likely to be continuously

adjusting its settings

-

When the ARC is placed between a transformer and the track the

final voltage that is available to the train or trolley is as much as a few

volts less than with a direct connection without the ARC. If you need to

have your train or trolley to run at high speed you may need to provide a

corresponding higher voltage to the ARC.

|

| |

| |