-

The Blinking Auto-Reverse Controller (BARC) makes running trolleys and other

point-to-point railroad engines a

simple and enjoyable experience -

Even though the

unit was initially called the "Basic" Auto-Reverse Controller its microprocessor brain gives it a host of features in a

small package -

The only connections are to your DC power supply and to the track.

-

Since the BARC controls your

trolley by time you can run it on a point-to-point or loop layout with our

without cut rail and diodes that are normally used at both ends.. -

If you choose

to use the cut rail and diode that such

systems traditionally use at each end

click

here for information on how this works and how to make your own track sections

|

(Although the term "trolley" is used in the notes below the BARC

will work with any small DC powered engine including G, HO, N and TT scales) |

|

|

Features

- You supply

DC power from your power supply to the BARC

- Since the

BARC can control the high and low speed of the trolley power can be supplied

from a fixed output 12-20 volt power supply, such as a

"wall wart"

-

A potentiometer, labeled

"Time", is used to set the

time that the trolley will run between reversals. This time can range from a few seconds

and over 8 minutes.

-

A second potentiometer,

labeled

"Speed", is used to

adjust the high and low speed setting of the trolley

- If

cut track & diodes are used the trolley goes to one end of the track, stops where it enters the diode protected

section and waits until the relay reverses the power

- If

cut track and diodes are not used you can manually set a stop point

where the trolley will stop and wait for the total time that you

selected to expire before it reverses.

- When the

relay reverses the trolley goes to the other end and the process repeats

- A set of 3

LEDs is used to show the time setting and the time remaining as the trolley

runs

- The same

LEDs also show the number of "laps" or reversals that have taken place.

- A fourth

LED indicates whether the running / delay time is always the same or is set to be changed randomly

- A

"deceleration point," where the trolley will begin to slow down, can easily be

set as the trolley is running

|

|

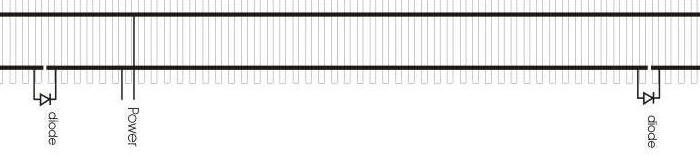

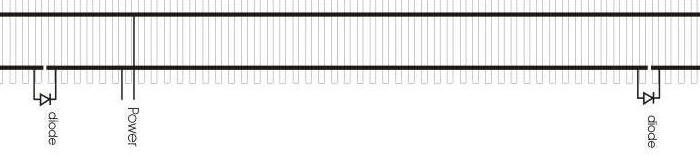

Track Preparation

for Those Using Cut Track & Diodes

-

Both track sections need to be cut

on the same rail and both diodes must be installed with the same polarity, that

is the band on the diodes must point in the same direction. Note that the

drawing above is for a G scale layout. If you work with HO the diodes must

have their bands pointing in the opposite direction.

|

|

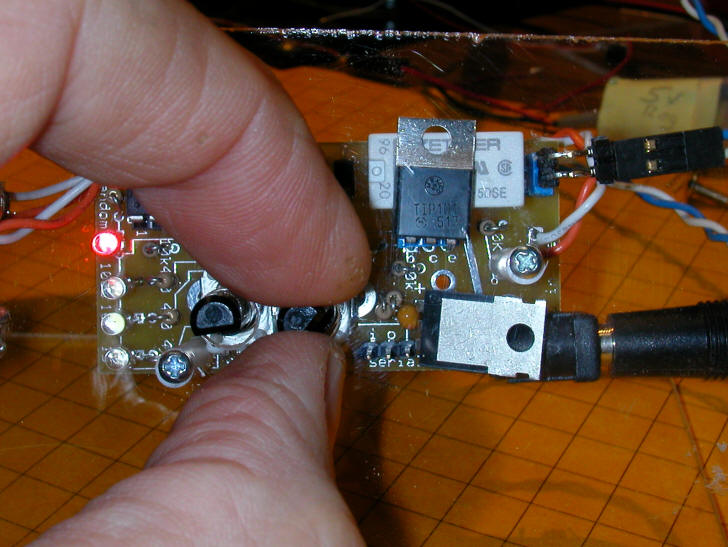

Power Connection

-

Power from your DC train transformer

or power pack

can be connected directly to the power terminals on the board

-

a

minimum of 7 volts is needed for

operation but 12 volts is preferred

- you may use an inexpensive train power pack

or even a DC "wall wart" style power supply

- the maximum speed of the trolley is

determined by both the power output of your power supply and the high speed

adjustment on the BARC

-

The power from your DC power

supply goes to the coaxial connector labeled "DC In"

-

The track is connected to the female

connector labeled "Out"

|

|

Power

Supply Precautions!

|

Setting Maximum & Minimum Speed

- The maximum speed of the trolley is determined by the voltage

supplied to the BARC by your DC power supply.

- In addition you can set the top speed to a lower rate by

following this procedure:

- Place the trolley in the center of the track

- Hold the "Set Max/Min Speed" button when you apply power to the BARC

- The 10's and 100's LEDs will flash. release the "Set

Max/Min Speed" button

- The trolley will begin moving in one direction

- Adjust the speed potentiometer (the one on the left) to increase

(clockwise turn) or decrease (counter clockwise turn) the top speed

- If the trolley comes to the end of the track and stops just

momentarily press the "Set Deceleration" button to reverse the trolley and

continue adjusting

- When you are done adjusting the top speed briefly press the "Set

Max/Min Speed"

button.

- The 10's and 1's LEDs will flash

- Adjust the minimum speed with the Speed pot

- Briefly press the "Set Max/ Min" speed button when done

- The BARC will remember that top speed setting, even after power

is removed, and use that settings until you reset it. Note:

while the trolley is running the low speed setting is

dynamically determined by the position of the Speed pot. that

is, you can move the pot as the trolley runs at its low speed and

either increase or decrease its speed.

|

Setting Acceleration /

Deceleration Rate

- The rate at which the trolley speeds up going from its slowest

to fastest speed and the rate at which it slows down is preset at a

rate that is likely to satisfy most situations

- If you would like to experiment with changing this rate follow this procedure:

- Complete the Set Maximum & Minimum speed as described above

- When done hold the "Set Max/Min Speed" button for

several seconds as the lights flash quickly

- When the flashing stops release the button

- Use the Speed pot to set the rate of acceleration /

deceleration.

- The full counter clockwise position gives a very fast

acceleration / deceleration while the full clockwise position gives

a very slow, gradual rate of change

- The trolley will continuously accelerate & decelerate to show

your selected setting, pausing for1 second at the maximum speed and

again for 1 second at the minimum speed

- Remember that briefly pressing the "Set Deceleration" button

will reverse the trolley should you run out of track

- Briefly press the "Set Max/ Min" speed button when done

- The BARC will remember the rate you have chosen.

|

Setting Time

- When the unit is first turned on the 3 red LEDs flash together

showing the version number of the software. (Version 5.2, for

example, would flash 5 times, pause briefly, then flash 2 times)

- During this flashing you have an opportunity to change the time

setting.

- The speed potentiometer, the one to

the right, makes time adjustments

- Turning the potentiometer counter clockwise decreases the time

and turning it clockwise increases the time

- The time range is from a few seconds to 512 seconds, a bit over

8 1/2 minutes.

- You will note that there is a slight detent, or bump in the

potentiometer movement, that you can feel when you pass the center

point

- If you turn the Speed potentiometer while the LEDs are flashing

out the version, the

LEDs will begin to flash out the time in seconds.

- The LEDs are labeled 1, 10 and 100. To indicate a time of

135 seconds the 100's LED would flash once, the 10's LED three times

and 1's LED five times.

- Each time the potentiometer is moved the time will change the time and

the unit will flash out the new setting.

- If you stop adjusting the potentiometer and allow the new time

to be flashed out three consecutive times the time will be stored

and the unit will start operating.

Note that time can be adjusted at any time during the

BARC's operation by turning the potentiometer a bit either way.

This will put you back in the mode described above. Note:

this feature removed 6-20-06

|

Random Time

- To make the time between reversals

somewhat random hold button 1 for a full second as the unit is

turned on. The red Random LED will light. Repeating this

procedure will turn off the random function.

- The random time is computed using

this formula: 1/2 of the time selected is added to a random

number between 1 and 1/2 of the time selected.

- For example, if the time were set

to 200 seconds the random times would be between 101 and 200

seconds. If 120 were set the random time would be between 61

and 120 seconds.

- Using this formula insures that

your trolley will have enough time to traverse the track before it

reverses since the time is never less than 1/2 of what you have

selected.

|

|

Getting started

-

Install cut / diode equipped track

at each end of the line of track

-

Connect the unit to the

DC output of your power supply.

-

Connect the output of the unit to

the track

-

Place a trolley, small engine or

rail car on the track

-

Turn on the power

-

Adjust the time with

the Time potentiometer

-

After the BARC initializes your

engine will begin its journey in one direction or the other

-

Once it hits an end it will delay,

reverse and continue

|

|

Setting a

Deceleration Point

-

As the trolley

approaches the end of its run you can set a deceleration point where

the BARC will slow the trolley to a lower speed as it enters the

diode protected end of the track and stops

-

Hint: let the

trolley run a few laps before setting the deceleration point.

-

Press and hold the "Set Deceleration" button when you want

the deceleration to begin

-

Release the "Set Deceleration" button once the lights begin

to flash rapidly

-

You can now use the speed potentiometer to adjust

the low speed setting

-

This will be necessary if the speed is set so low

that the trolley stops rather than slows to a crawl

-

Once set the BARC will remember the deceleration

point until you either choose another, earlier deceleration point

-

If you want to do a later deceleration point do a

complete reset first.

|

Time Reported During Timing

- As the BARC operates it flashes out the time remaining until the

trolley is

reversed.

- You may notice that the flashing will frequently skip a second

or two as it reports, for example, 33, 32, 31, 30, etc. This

happens when the time needed to flash out a report exceeds one second.

|

A Note About Time

- The accuracy of the time reported by the BARC is reasonably

precise

- The time between trolley reversals can be off by a few seconds

due to the varying time needed to report the number of laps run and

the time needed to accelerate or decelerate.

|

Laps Completed Report

- Each time the time count reaches zero the BARC reports the

number of times the unit has reversed the trolley. You can

think of this as the number of "laps" that have been completed.

- The report is similar to the time remaining report except that

all 3 LEDs flash before and after the laps report and the report is

flashed out somewhat more slowly than the time remaining report.

- If the number of laps exceeds 999 the counter will continue to

report by flashing the 100's LED correctly. If you are on the

1345 lap, for example, the 100's LED will flash thirteen times, the

10's four times and the 1's five times. If you let it run for

a few weeks it will eventually reset to zero when it gets past 2^16

which equals 65,535!!

|

Complete Reset

- The BARC can be completely reset to

its factory configuration by following this procedure.

- Turn the BARC off

- Hold BOTH the "Set

Deceleration" and "Set

Maximum" buttons down

- Turn on the power to the BARC

- All four LEDs will begin to flash

- Hold the buttons until the LEDs

stop flashing. This takes about 3 seconds

- Release the buttons and all is

reset

- Releasing the buttons before the

LEDs stop flashing will abort the reset

|

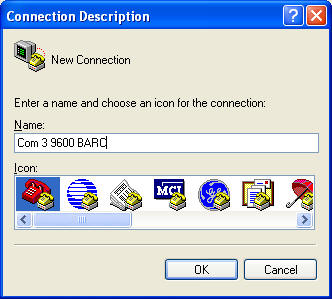

An Added Bonus!

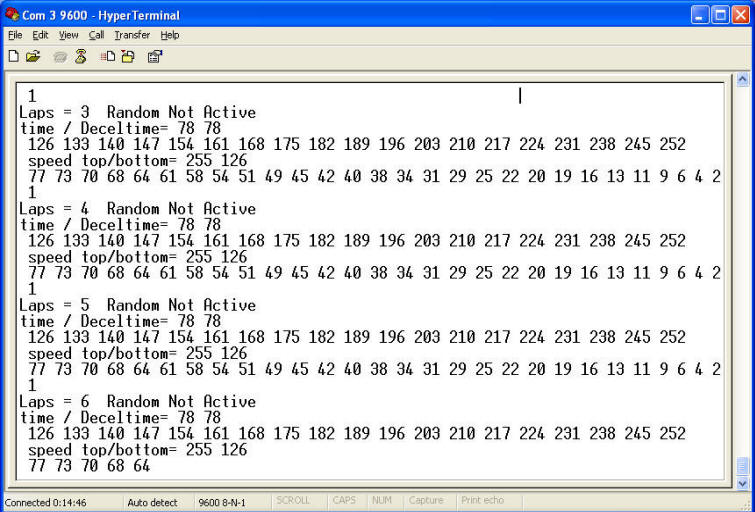

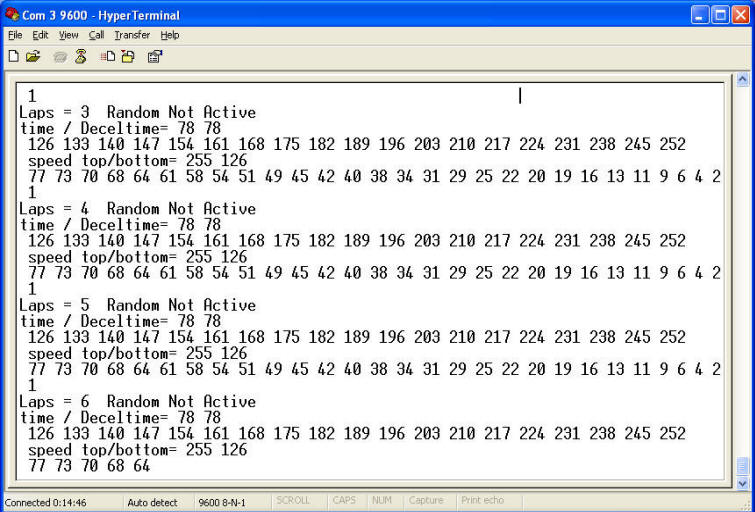

- If your computer is equipped with a standard 9 pin serial port

you can see the progress of your BARC and see the total laps

completed by your trolley.

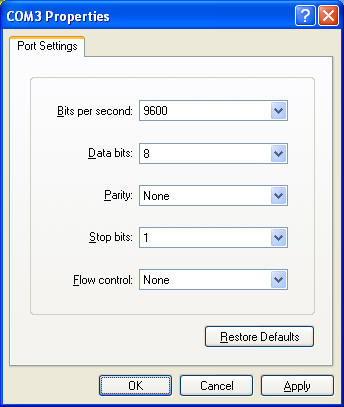

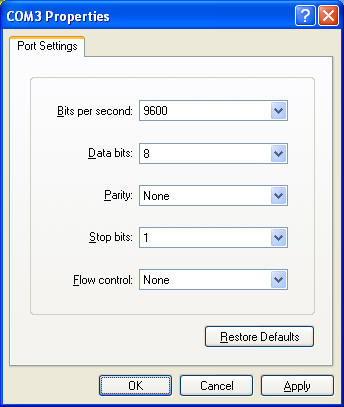

- Receiving reports from the BARC

involves starting a terminal program, like HyperTerminal. Set it to

2400 baud, No parity, 8 bits, and one stop bit. It must also be

set to use COM1 (or whatever com port you prefer) rather than a

modem.

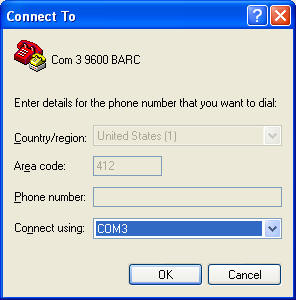

The images

below show how I set up my computer. To get started on a Windows

98, 2000, ME or XP computer click Start then All Programs then

Accessories then Communication then HyperTerminal. If HyperTerminal

is not there you may have to install it. For instructions on how to

do so just search Google for "Install HyperTerminal".

Here is a sample link on how to do the install from IBM's web site.

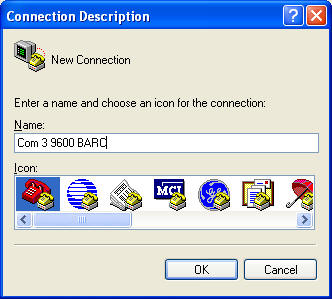

When you first start HyperTerminal

you must create a new connection. Type a name for the new

connection (I used Com3 9600 BARC) in the Name box.

Click OK

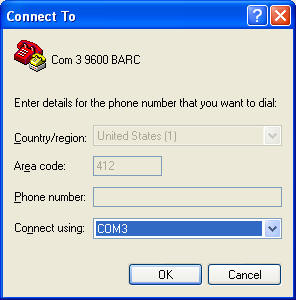

In the Connect To box I selected Com3 - you are more likely to be

using Com1

Click OK

Change the next screen so that it

looks like this:

Make sure Flow Control is set to "None"

Click OK

Connect the 9 pin serial plug to your PC's serial

port. The cable is short and may require a serial extension

cable. Plug the 2 pin header into the board where it is

labeled "serial" - make sure the white wire on the connector that

goes to the board goes to the pin marked "-".

If necessary click

on Call / Call to connect to the port. Once connected you

should see information like that show below on your screen.

|